Data-driven manufacturing means using real-time data from machines, sensors and software systems to optimize production, capacity planning, maintenance, and recovery operations.

Innovative Approaches to Streamline Manufacturing Capacity Planning

- The Rise of Data-Driven Manufacturing in Modern Industry

- Why Capacity Planning Depends on Data Accuracy and Availability

- Integrating Data Recovery Systems Into Manufacturing Workflows

- Predictive Analytics for Smarter Capacity Forecasting

- Cloud and IoT Integration for Real-Time Production Insights

- Automating Data Migration to Eliminate Bottlenecks

- Building Recovery-Ready Infrastructure for Manufacturing Resilience

- Frequently Asked Questions

Picture this: you own a factory where the machines talk and notify you of any internal problems on their own before they turn into bigger ones, where data moves efficiently and production schedules automatically adjust themselves before any problem arises.

A factory that works on proactive strategies rather than reactive ones. Sounds too good to be true? Well, not anymore, because you can turn this into a reality with the help of smart innovations, as this is the period of data-driven manufacturing. You will be surprised to know that already around 85% of manufacturing companies today use some form of digital transformative initiative. (Source:Gitnux)

In this guide, we’ll dive deeper into this topic and learn how real-time data analytics, AI forecasting, and cloud systems are revolutionizing the industry. We will also discuss how to choose the right capacity planning software. Read on!

The Rise of Data-Driven Manufacturing in Modern Industry

In this era, manufacturing industries are all about smart, data-driven process designs, which is a response to growing complexity in the supply chain market and rising expectations for faster delivery.

Earlier, this was not the scenario. Traditional approaches relied on manual labor, tracking and periodic reporting. Although things were working just fine with these methods, they really did not capture what was happening inside the factory in real time.

By shifting to an advanced, data-driven regimen, machines, production lines, and enterprise platforms continuously generate data that can be easily analyzed and turned into useful insights. This allows manufacturers to detect inefficiencies earlier, adjust workflows quickly, and operate with far more precision than ever before.

CASE STUDY

How an Automotive Factory Improved Output With Data-Driven Manufacturing

In 2015, an automotive components manufacturer experienced significant growth in its operations. But with that expansion came a few setbacks: unpredictable delays, outdated capacity planning spreadsheets, and a manual data recovery process that pulled all the operations down with it.

After the integration of an AI-driven capacity planning platform, cloud-based IoT sensors, and an automated data recovery module connected to their ERP. They found themselves back on the track. Within the first few months, the results were extraordinary:

- 20% improvement in production scheduling accuracy

- 30% reduction in machine idle times

Why Capacity Planning Depends on Data Accuracy and Availability

Capacity planning is one of the most important aspects for any manufacturing company. Inaccuracies in it can lead to flawed forecasts, oversupply, shortages, and stressful last minute adjustments. All of this will ultimately contribute to operational failures and monetary damages that can easily be avoided with a little bit of planning.

Complete and accurate data from sources like machine utilization rates, labor availability, and inventory turnover can provide manufacturers with real-time dashboards and accuracy across every stage of production.

Integrating Data Recovery Systems Into Manufacturing Workflows

The data recovery systems you integrate will directly influence your production efficiency. This is a strategic decision that can make or break the entire process. The best systems integrate securely with your top-rated manufacturing ERP and provide important information in real time, and minimize downtime.

For a seamless integration, keep the following points in account:

- Assessing existing infrastructure to identify data silos and make sure all data follows company standards.

- Check if the data is accurate, clean and consistent across all the systems.

- Build a roadmap that aligns with your current system and is capable of future growth requirements.

This will help you implement a robust recovery mechanism and enforce governance and security.

Predictive Analytics for Smarter Capacity Forecasting

A few years ago, capacity forecasting and Financial Planning in the manufacturing field meant manual assumptions and historical averages. Doing things this way involved a greater risk of downtime and loss, as these assumptions were not as much reliable.

Predictive analytics changes the whole picture by deeply analyzing trends, identifying patterns and estimating future outcomes with a lot more accuracy. This reduces production slowdowns, inventory shortages, shifts in customer demands and more such factors that affect a company’s sales and manufacturing needs.

DO YOU KNOW?

Manufacturers that leverage real time data systems experience up to 50% fewer unplanned equipment failures than those that do not. This is because, with real time data tools, machines actually signal them when they’re about to break down before they actually do, saving them from unforeseen disruptions.

Cloud and IoT Integration for Real-Time Production Insights

Cloud computing and IoT devices keep the whole modern manufacturing landscape connected. The integration of sensors, connected machinery, and cloud-based platforms gives manufacturers instant visibility into production performance, remote monitoring capabilities, faster issue resolution, and automated data collection across the plant. For easier integration, outsourcing is also a great option.

Automating Data Migration to Eliminate Bottlenecks

Data migration involves risks of errors, delays, and system conflicts, especially if done manually. To resolve this issue AI-driven migration tools have made their debut in the market. These boost the implementation speed, prevent inconsistencies, lower operational disruption and ensure continuous data availability.

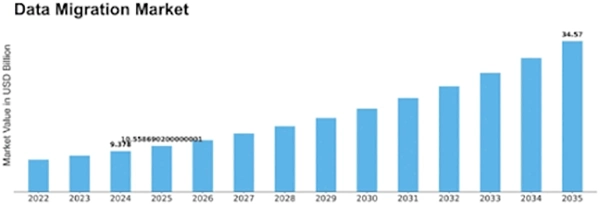

Due to all these benefits, the automated data migration market is on the rise. It was reported to be worth 9.378 USD billion in 2024 and is forecasted to reach 34.57 USD billion by 2025.

Building Recovery-Ready Infrastructure for Manufacturing Resilience

A resilient manufacturing system is always ready for any kind of system failures that might occur in the future. And the factors fueling this proactive approach are a hybrid cloud environment, automated failure solutions, strong cybersecurity layers, distributed storage networks, and modular production systems.

All this combines reliability and flexibility that helps manufacturers develop operations that are not only efficient but recovery-ready as well.

In the end, it is safe to say that modern tech like AI and ML is reshaping the manufacturing industries by blending data together in the process, changing the way industries plan, produce and recover data. Such readiness ensures that even when equipment fails, the supply chain will not be disrupted, and essential operations will continue as expected.

Frequently Asked Questions

What is data-driven manufacturing?

Why is accurate data essential for capacity planning?

Having accurate data is crucial for capacity planning as it ensures correct forecasting, prevents overloading machines, avoids material shortages, and reduces downtime.

How do data recovery systems support manufacturing operations?

Data recovery systems play a major role in manufacturing operations as they automate data backups. Reduce downtime and ensure a smooth recovery after failures or cyberattacks.

What features should I look for in a capacity planning software?

In a capacity planning software, you should look for real-time analytics, AI forecasting, ERP integration, scenario planning, automated data migration, and cloud + IoT compatibility.

“Stop selling. Start helping.” — Zig Ziglar (Author) And the personnel who sell the hardest to clients and help the…

Digital storefronts are always at risk of losing files. In the case of a system failure, the effects on sales…

USB drive not showing up, acting slow, unreadable, or showing as RAW? Please, don’t format it immediately. I am going…

“Those who do not live in the past cannot live in the future.” — Lord Acton (19th-century historian) This is…

Healthcare data is dynamic. It travels through cloud backups, billing offices, nurse stations, insurance systems, reception desks, and occasionally across…

You’ve poured your heart and soul into creating your website. Every blog post, product description, and stunning image is a…

For a long time, remote desktop technology was the domain of IT support technicians and spreadsheet-heavy administrators. If the connection…

Are you wondering what speech basics are and what you capture, how to store it and analyse the same without…

If your Android suddenly shows Safe Mode, or you just want to undo Safe Mode after finishing your task, you…