Data migration software helps ensure that all records, settings, and production data move safely to the new system.

Smart Manufacturing Software: Key Features for Reliable Data Migration and Recovery

- The Growing Importance of Data in Modern Manufacturing

- Why Data Migration Is Key During Software Upgrades

- Automated Backup and Rapid Data Recovery Capabilities

- Cloud Integration for Real-Time Access and Reliability

- Data Security and Compliance in Manufacturing Software

- Predictive Analytics for Preventing Data and Process Loss

- Future-Proofing Your Manufacturing Operations

- Frequently Asked Questions

Have you ever considered what would happen to a manufacturing facility should it upgrade its software in the middle of the production process? Well, it is higher than you may imagine. A lapse in one transfer of data can bring all the production lines to a stop, corrupt quality records, and cost companies millions of dollars in lost time. The current industry statistics show that 6 out of 10 manufacturers have lost data to some extent in the transition process of the system, and this is not a trivial matter.

The in-the-field manufacturing environment is now incredibly dependent on real-time data to make decisions, streamline work processes, and ensure Product quality. However, with the modernization of operations such as smart manufacturing software, a challenge arises to the facilities on how to migrate and secure their valuable data without interference with the production process. Luckily, the current ways of solving problems have been fitted with sophisticated features, which are specifically meant to solve these issues. Want to know how? This is what you should know about this post. Keep reading!

KEY TAKEAWAYS

- Reliable data migration can help you prevent costly production disruptions.

- Real time data drives faster and smarter manufacturing decisions.

- Automated backups ensure instant recovery after failures.

- Cloud systems improve access, storage and safety.

The Growing Importance of Data in Modern Manufacturing

Remember when production used to imply hand-written logs, paper-based quality checks, and gut-feel decisions? Well, those days are long gone. The new manufacturing plant is a place that produces enormous volumes of data day after day – machine performance indicators and inventory levels, quality control indicators, and supply chain information.

This information does not exist on a computer screen as mere numbers; it is the blood of effective functionality. It helps manufacturers anticipate failures of equipment, optimize production, minimize waste, and guarantee quality of the products. This is where MRP software for make-to-order manufacturers is a key. To comprehend that, we will take the following example: a factory monitors the temperature on its production line. Even a minor variation in these measurements can be a sign of a possible flaw, as the teams will be able to deal with the problems before thousands of defective products have been produced.

Why Data Migration Is Key During Software Upgrades

The process of upgrading to smart manufacturing software should be forward-moving rather than jumping into the abyss. However, the action of data migration is considered as an afterthought in most facilities, only to start experiencing severe issues in future. It is difficult to take decades of historical data, settings and operational parameters and recreate them without losing any of the accuracy or context.

Lack of planning the migration process may lead to the incompatibility of data formats, failure of integration with the existing equipment and the incompleteness of the transfer of essential records. It is easy to imagine that when you have spent an entire day setting up new software, you only find that your data on quality control in three years past has been corrupted or lost. This may slack it all, and direct it to the very core of your productivity.

PRO TIP

During migration, always have a parallel system that is running, i.e. your old software running, as you test the new one, so that you can identify any discrepancies in data before you get on to full live mode.

Automated Backup and Rapid Data Recovery Capabilities

You know that old saying, “Prevention is better than cure”? It fits manufacturing data like a glove. The smartest move isn’t scrambling to fix data loss; it’s making sure you never lose data in the first place. These days, smart manufacturing software comes with automated backup systems that take care of everything for you. No need to remember to hit ‘save’ or worry about it.

So, if disaster strikes, a cyber attack, a crash, or someone hits the wrong button, you don’t have to panic. The system can snap your data back in minutes.

Cloud Integration for Real-Time Access and Reliability

Cloud-based integration has really shaken up the way manufacturing teams handle their data. Before, with old-school on-premise systems, everything sat in one spot. If something happened there, a power outage, a fire, you were out of luck. And good luck trying to work from somewhere else, with smart manufacturing software in the cloud, things look totally different.

Now, you can pull up real-time data from anywhere or any device. Every facility stays in sync automatically, so you’re never stuck with outdated info. Need more storage? Just add it, no need for new servers or hardware. Plus, your data is backed up in different places, so if one region goes down, you don’t lose everything.

Data Security and Compliance in Manufacturing Software

Manufacturing data isn’t just numbers on a screen. It is your edge in the market, and its what keeps you in line with regulations. You can’t afford to let it slip. That is why picking smart manufacturing software with strong security isn’t just smart, it’s necessary. Attacks on industrial facilities have shot up lately, so you need tough protection.

The best manufacturing software steps up with serious security. Things like end-to-end encryption, role-based access, multi-factor authentication, and round-the-clock monitoring. With these in place, only the right people see

DO YOU KNOW?

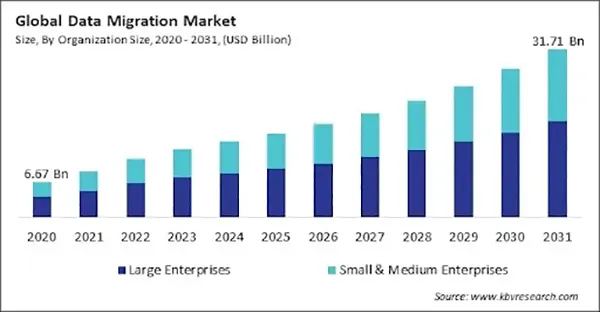

The global data migration market was measured at USD 6.67 billion. The market is expected to grow and reach USD 31.71 billion by 2031.

Predictive Analytics for Preventing Data and Process Loss

Forget about the old days when manufacturers just waited for things to break and then assembled to fix them. Predictive analytics changed everything. Now, smart manufacturing software digs through heaps of operational data and does more than just watch; it actually helps you stay ahead. It predicts when equipment will fail, spots quality problems before they turn into real headaches, figures out how much data storage you’ll need, catches weird activity that could be a sign of a security threat, and even fin-tunes your maintenance.

Machine learning is at the heart of this. These algorithms track thousands of data points nonstop, learning exactly what normal looks like for your operation. The second something looks off, the system shoots an alert to the right people, so they can jump in and fix things before they spiral.

Future-Proofing Your Manufacturing Operations

Smart manufacturing software has come a long way. It’s changed the way factories handle, protect, and use their data. And honestly, we’re just getting started. Down the road, get ready for even smarter AI systems, sharper edge computing, and way better connections between different platforms. Plus, you’ll see these systems working hand-in-hand with cutting-edge tech like digital twins and IoT sensors.

Frequently Asked Questions

Why is data migration important during a manufacturing software update?

What causes data loss during migration?

There can be different reasons for data loss during migration, including incompatible formats, incomplete transfer, poor planning, and outdated equipment connections.

How do automated backups help manufacturers?

Automated backups regularly save data in the background, which help teams restore everything quickly if something goes wrong.

Why choose cloud-based manufacturing software?

Cloud based manufacturing software is an excellent choice as it offers real-time access from anywhere, safer storage, and automatic syncing across all facilities.

Most people think hackers need advanced tools to find security gaps. Sorry to break the news, but sometimes, Google is…

If you are a part of any business, you might have attended meetings. And in case you were connected to…

SSD data recovery software can retrieve data that has been deleted, damaged, or otherwise rendered inaccessible from the SSD hard…

How can I improve the performance and grow my business? My team is already occupied with several projects, how do…

It feels very frustrating to lose all your digital data due to just one panic mistake of selecting a password…

Special Purpose Vehicles (SPVs) are a type of legally structured company. They are created by parent companies, usually with temporary…

Web cache and cookies make browsing faster by saving logins, settings, and site data. But over time, they can slow…

Finding the best tools for your company feels like a big job. You need systems that actually help your team…

In the digital age, instant messaging apps have become an essential part of our daily communication. Whether for personal use,…